CHUNDI Flocculant for Mineral Separation and for Alumina Red Mud Sedimentation

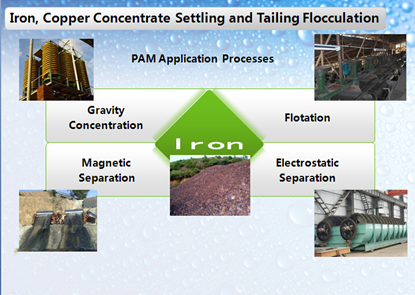

Mineral Separation Flocculant

Product introduction

The mineral separation flocculant takes important part in solid-liquid separation process of beneficiation. It can not only separate minerals and ores, but also can be used as a flocculant in wastewater treatment, as well as sealing mining pipelines.

The special grade of polyacrylamide offered by CHUNDI is oriented to different mineral dressing needs. They have good stability, strong adsorption and bridging ability, good flocculation effect, fast settle speed, and good resistance against high temperature and salinity.

Application areas

Iron, copper aluminum, nickel, gold, lead-zinc, phosphate, coal mine, titanium, titanium dioxide, tungsten ore, etc.

Alumina Red Mud Sedimentation Flocculant

Product Introduction

Sedimentation and separation of red mud is an extremely complex physical and chemical process. The Bayer process dissolving pulp is a suspension formed by red mud and sodium aluminate solution. Due to the complex physical and chemical interactions between the red mud particles and the solution, the phase composition, distribution, surface morphology of red mud particles, solid content of red mud slurry, liquid phase composition, red mud slurry temperature, etc. All have significant effects on the sedimentation and separation process of red mud slurry.

By adding specific flocculant can greatly increase the settle speed of solid-liquid separation. The mechanism of high-molecular flocculants lies in the effective coagulation betweeen the red mud particles through adsorption bridges, surface adsorption and charge neutralization, and the formation of “large particles”, which greatly accelerates the settling velocity. Different dissolution ore pulps have different properties, and the appropriate polymer flocculants must be selected through experiments before achieving high efficient separation of red mud on site.

Product Effect

1.Strong focculation, stable flocculation process

2.The formed flocs are small strong and anti-shear

3.Effectively reduce the content of suspended matter in the aluminate liquid and increase the productivity of the subsider.

4.Improve clarity and overflow quality

5.Underflow liquid-solid ratio is low

6.Prevent red mud from swelling

7.Less affected by temperature and PH change

Emulsion Type Settling Flocculant for The Red Mud of Alumina

| Appearance | UL viscosity | PH | Specific Gravity | Flash point |

| Thick Fluid | 5-9cps | ≥6 | 1.03 | >100℃ |

Dry Powder Type Settling Flocculant for Washing The Red Mud of Alumina

| Appearance | Solid Content | Dissolving Time | Flash point |

| White Granule |

≥88 |

≤60 |

>100℃ |

Packing & Loading

1. Powder: PE bag; Kraft bags, 25kg/bag, 1000kg/pallet, 40bags/pallet, or according to the user's requirement.

2. Emulsion: Plastic barrel and with each barrel containing 1000L or 25L, or in accordance with customers' demand.

Our Advantages

1.Cooperated with domestic big enterprise who has professional R&D and manufacturing experience for 20 years to develop PAM meeting every demand from different industries.

2.Full-automatic advanced production lines, make sure products are in stable quality.

3.300,000 tons total annual capacity , guarantee timely delivery.

4.More competitive price with superior quality.

5.Professional after-sales service, solve problems instantly.

6.Customized product developing service available

FQA:

Q:Do you provide samples? is it free?

A:Yes, we could offer the sample for free charge but delivery freight will be borne by buyer.

Q: What's your payment terms?

A: T/T in advance are highly recommended, 30% deposit before producing, 70% balance against B/L copy in 7 days.

Q:What is the delivery time?

A:It depends on order quantities. 7-15 days after receiving advance payment.

Q:What’s your MOQ?

A:Usually Our MOQ is 1MT .

Q: Which information in the inquiry you should send us?

A:Chemical name/ content/spec./exact quantity/ usage or field/destination port/other special requirements.

Contact

For more product detail and best price & delivery time, please feel free to contact our team:

Email: info@qdchundi.com ; william@qdchundi.com

Mobile: +86 15063003321; +86 18561755559